An Asset Inventory and Tagging is an opportunity to correct financial ledger data to a standardized nomenclature, to clear up any ghost assets (for-profit organizations may see a property tax reduction from this), and to better identify equipment needs (where equipment is lacking or requires replacing). Asset tags improve the accuracy of future revisions to data in your asset ledger by allowing verification that the asset tag number observed on the physical asset matches the tag information on the asset record about to be modified.

The Asset Inventory and Tagging process begins with the definition of scope and requirements.

The scope – which items are included and which are not – should match your capital threshold (for more on this, check out this blog). Additionally, if your asset ledger contains items located at sites other than the main facility, you will need to determine which sites are included in the inventory. (If a site does not contain items within the threshold, it would be most sensible to exclude it from the inventory.)

Requirements will address, at the least, the tags to be used, and the amount of information to be captured. Asset tags provide a unique identifier for each asset by way of a barcode number. Before you get started on the inventory, you need to define exactly which kind of tags you will be using, approximately how many will be needed, and how the tags should be affixed to assets. There are many different types of tags available; be sure to select one that can withstand the intensive cleaning requirements of a healthcare environment.

The amount of tags you will need for an inventory will depend on the size of your facility and estimated number of assets to be tagged (this may be lower for a facility consistently using tags already). As mentioned in a previous post, take care to also standardize methodology of tag application. For example, instruct the Inventory and Tagging team that tags should be attached to assets on the upper right corner of the front of the item; this will improve efficiency of data collection on future Inventories.

Set forth the types of information to be recorded for each asset during the inventory.

We recommend collecting the following pieces of information for each asset (as a system):

- Asset Tag Number

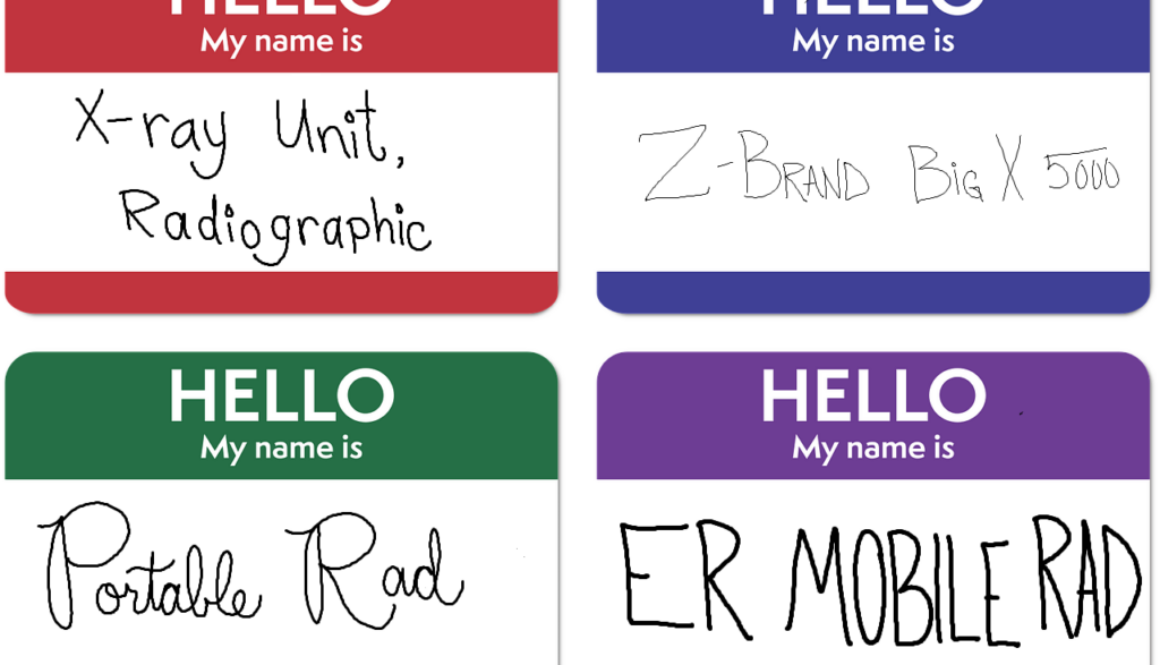

- Equipment Type (this is the standardized name)

- Manufacturer

- Model

- Age

- Location 1 (Building/site name for Inventories including sites in addition to the main facility)

- Location 2 (Department or Room)

- Serial Number (where feasible and helpful; examples: medications dispensing, ventilators)

- Notes (used as needed for any additional identifying information)

Next plan your resources and schedule.

Both the size of the Inventory team and the time required to complete the process will be driven by a number of factors:

- The size of your facility (and whether you have any off-site locations to include)

- the estimated number of assets to be inventoried (including those already tagged, because information must still be captured on those)

- The amount of time in which you would ideally like the inventory and tagging to be completed (you’ll want to keep this to a minimum so that bringing the asset ledger current after reconciliation won’t take too much work)

Once the Inventory work is complete, be sure to allow plenty time in your schedule for reconciliation of the data collected then to the asset ledger. To avoid errors, this portion of the work is best completed by a single person.

As you decide when to begin the inventory and tagging, check in with department directors to advise them of the process (so staff will be aware the Inventory Team will be in their areas, including those with patients) and to learn of any potential scheduling conflicts.

Ask what is the best time of day to get into Surgery to perform the inventory (when their cases start wrapping up for the night), and schedule specific times to inventory areas that can be challenging to access, such as IT, Radiology, and Pharmacy.

While the process of Inventory and Tagging is rather involved, its benefits are great. Once the Inventory Team has completed their work, the data gathered is reconciled to the asset ledger, resulting in a much more accurate record of your facility’s assets that will be easier to navigate and to maintain. If you’ve chosen to use asset tags, the tag numbers can also be useful for coordinating relocation activities.

As described in our previous blog post, Is Your Medical Facility Haunted by Ghost Assets?, a healthcare asset listing containing items that do not actually exist at your facility is problematic. So once you have had a healthcare asset inventory and reconciliation to remove those pesky ghost assets, you’ll want to keep your asset listing clean. This can be challenging because maintaining the integrity of your asset listing is a collaborative effort, but these tips can help.

First, ensure that you set up clearly defined policy and procedures for tangible personal property and that the appropriate parties at your healthcare facility are aware of and fully understand them. This is the foundation of successful healthcare asset management.

Your healthcare asset policy and procedures should be written and made available either in print and/or through an easily accessible, shared location such as your intranet. Begin this document with an explanation of its objectives along with some examples of why it is important to properly track assets, such as insurance purposes or government regulations.

Next, set forth your definitions. For capital assets, explain that the items must have had an acquisition cost, regardless of their current value, equal to or above your capitalization threshold (include the actual dollar amount) for this classification. Include any other terms you will reference throughout the document.

Outline responsibilities. If you expect that department directors or managers will perform the work of reporting asset transfers and disposals and that Receiving will report asset acquisitions, ensure that they understand this responsibility and that they know who to report this information to and how to do so. By requiring that new items are tagged upon receipt by a single entity, it will be easier to ensure only assets within capital threshold will be tagged and that the tags will be placed in the appropriate position on each item.

Associating each asset with unique tag numbers can make asset tracking easier. These tags will serve only to maintain an accurate asset log and will be a different and separate type of tag than the kind used by Biomedical Engineering, which are used for equipment maintenance purposes. Note that while it is possible to simply record serial numbers instead of tagging, that method can make routine audits more difficult, as serial numbers are often located on hard to see surfaces of equipment. If you plan to record both serial numbers and tag numbers, be sure to establish which type of information will be the primary component by which each asset will be identified. If tags will be used, describe tagging in full; include an explanation of:

- What to tag and what not to tag, some examples are:

- IT items like computers may have a different tag, and many items will also have a BioMed tag. Do not cover these tags; they are used for other types of tracking. Some of these items will fall beneath the capital threshold and do not require an asset tag, while some will need an asset tag – carefully review the acquisition cost of the item against the capital threshold to determine whether to apply an asset tag.

- A tag number should be recorded for some items, like endoscopes, but cannot have a tag physically applied because of the cleaning process or other reason (explain what to do with the tag itself, perhaps require it be turned in to Accounting so that its unique number is not accidently reused, etc)

- Include a list of examples of items that should receive an asset tag

- Provide a point of contact to resolve any uncertainty over whether something should be tagged

- When to tag: all items should be tagged immediately upon receipt by (insert responsible party here)

- Where to tag so that the numbers can easily be seen when the item is in use

- Example: do not tag a bed on the back of the headboard as it will be completely out of view when a patient is in it; instead, place the tag at the footboard end.

- Set a rule of thumb as to the general location a tag should be placed on any item. For example, instruct that a tag should be placed at the top right side of any piece of equipment whenever possible. (Exceptions to this rule may be caused by insufficient surface area to apply the tag there, or there could already be a logo or other information there.) Consistently tagging items in the same spot will make it easier to find the tag number information in the future.

- How to record asset tags for each situation (acquisition, transfer, disposal)

- Create a standardized form that includes all required information to be completed for any of these asset activities and information on where to send the completed forms.

- A standardized nomenclature for consistent equipment description is fundamental to maintaining an accurate asset listing. Include an exhaustive list of asset types that should be used verbatim to describe items on the form.

(Here’s an example of why standardized descriptions are important. Imagine Intensive Care has a monitor in each patient room by ABC Company, and the model is Cardio Scope 700. Meanwhile, on patient floors there are monitors by XYZ Company called Mega Vitals 5. It is very likely that these two monitors will be described differently even though they are the same type of equipment. Examples might be: ICU Monitor and Vitals Monitor, ABC Monitor and XYZ Monitor, or Cardio Scope Monitor and Mega Vitals Monitor. In fact, it is even possible, especially if additional monitors are purchased after some time, that two of the same exact model of monitors could be described differently. Such variances will make it difficult to sort your data to view every monitor at your facility. It is better, therefore, to standardize on a description such as Monitor, Patient or Monitor: Physiologic because the manufacturer and model information will still be recorded in their respective fields and can serve as additional filters, if needed, without limiting the initial sort.)

- This is a good place to outline transfer and disposal policies

Finally, you may also want to include information on your physical inventory procedures and policy and even a record page to list the month and year each time an asset inventory and reconciliation is completed. Inventories should be performed at regular intervals to ensure tagging procedures are being followed appropriately, and the reconciliations will clean up any ghost assets that may have formed on your asset listing.

A well-organized and detailed document containing your tangible personal property policies and procedures is the first step to successful healthcare asset management. Other asset management tools, such as the standardized form for tracking asset activity mentioned above, will also make keeping up with assets much easier for everyone involved. Stay tuned to our blog for a post with more on that coming soon.

While the process of Inventory and Tagging is rather involved, its benefits are great. Once the Inventory Team has completed their work, the data gathered is reconciled to the asset ledger, resulting in a much more accurate record of your facility’s assets that will be easier to navigate and to maintain. If you’ve chosen to use asset tags, the tag numbers can also be useful for coordinating relocation activities.

Come Get To Know Us!

To learn more about Partners healthcare Group and the many services we offer, please visit us online at www.PHGWorks.com, call us at (615) 370-5014, or toll-free at 1-800-270-7582 . You can also visit us on Facebook, Twitter, Google or LinkedIn! We look forward to working with you in the future!